Low pressure PU processing technology

Low pressure PU processing technolgy is subdivided into the areas of pouring and injection processes.

Pouring units may be controlled manually, by robot or using lineal axes. The PU material (polyol and isocynate) is poured into the open mould. On completion of pouring the mould is closed until the PU material is fully reacted.

Injection units involve injection into the closed mould. After the material is completely reacted, the mould is opened and the product removed.

Pouring units are used for products whose properties should be modified by the use of granulates.

The advantages of low pressure PU processing technology with granulate dosing are:

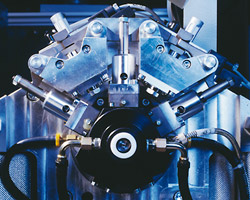

Polyurethane mixing technology with highest precision

Polyurethane mixing technology with highest precision

- Self cleaning mixing chamber

- Rinsing agent free production

- Mechanical synchronisation of component valves ensure highest precision;

unequal component distribution is avoided - Continual recirculation of all components

- Component change, shot to shot

- Precise addivtive dosing (up to six additives in addition to basic components)

- Precise granulate dosing (particle size up to 4mm)

- Fast screw change (manual or automatic)

Low pressure mixing head options

Low pressure mixing head options

Manually controlled mixing head

- ease of movement

- optional mixing head height adjustment

- flexible mould carrier adjustment, according

to customer's wishes - configurable working area, according

to customer's wishes

Automatic mixing head

Automatic mixing head

- automatic head transportation

- automatic pouring and injection process

- connection to rotary table and conveyors

Robot controlled mixing head

Robot controlled mixing head

- maximum user-friendliness

- graphically supported robot programming

- realisation of complex mould geometries

or multi-cavity moulds - freely programmable movement processes

- simple interface to rotary tabe or conveyor