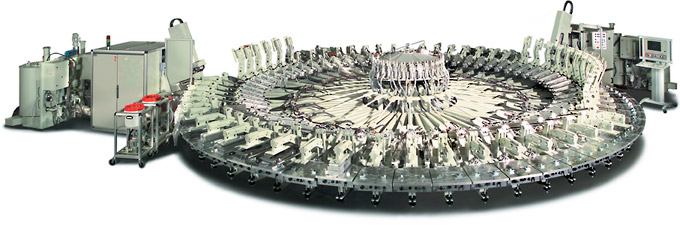

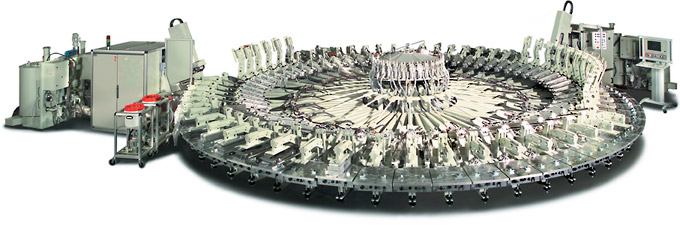

Rotary tables

DESMA has been developing and producing rotary tables in various sizes for the production of technical articles since 1960. There are two main types of rotary table.

Rotary tables for manufacture of poured articles

DESMA offers rotary tables for the production of poured articles. Pouring units, either manually or robot controlled, pass over the open mould and pour in the correct amount of material. The mould is then closed and locked. The material, usually foamed polyurethane, expands in the closed mould until final hardness has been reached. De-moulding follows later.

Rotary tables for the manufacture of injected articles

Such rotary tables are characterised by the injecting of material into the closed mould. Injection takes place using low pressure units in front of the rotary table. Moulds on these rotary tables, which may have 12, 18, 24 or 30 stations, open horizontally.

desma tec, plastic products, thermoplastics, vulcanized rubber, reactive, polyurethane machine, pu technology, micro injection, flame retardant, mixing head,

PU technology, Polyurethan, polyurethane, PU, PUR, PU gießen, pu casting, pu pouring head, Reaktionsspritzgießen, reaction injection moulding, pu casting parts, pu casting products, Feststoff, solid additives,

Blähgraphit, expandable graphite, Flammschutz, flame retardant, Gießroboter, casting robot, Mischkopf, mixing head, Niederdruck, low pressure, Hochdruck, high pressure, Kunststoffmaschine, plastic machine,

Hartschaum, rigid foam, Elastomer, elastomer, Weichschaum, softfoam, micro injection, Formica Plast, thermoplast, thermoplastic, Mikrocomposite, microcomposites, Nano composite, nano composites, spritzgießen,

injection moulding, Spritzgießmaschine, injection machine, Mikrospritzgießmaschine, micro injection machine, mikrospritzgießen, micro injection moulding, metal injection moulding, powder injection moulding,

ceramic injection moulding, Präzisionsspritzen, precision moulding, microsystem 50.